Introduction to 3D printing

3D Printing sounds like science fiction becoming reality. The promise of objects that can appear or be created anywhere. Wherever you are. At home, across the world or in space.…

Notes left by Franck Debane

3D Printing sounds like science fiction becoming reality. The promise of objects that can appear or be created anywhere. Wherever you are. At home, across the world or in space.…

Taken from 10 ways to inhibit innovation, here are 4 trends that what prevents innovation in companies. We exploite and dont explore Our focus on short-term results drives out ideas that take…

McKinsey Quarterly published an article “The social side of strategy” that includes examples how companies can leverage the wisdom of their own crowd (employees) into their strategy planning, also gaining…

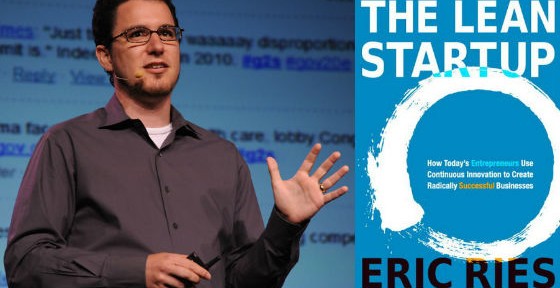

Eric Ries talks are great and his book is a must. It’s easy to read, practical with lot’s of real life examples and situations. If you have a specific idea…